Product

Product

Pogo Pin Solution

Final Test Solution

WLCSP Probe Head

Coaxial Socket

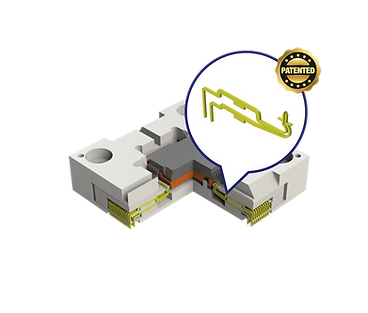

Coxial WLCSP Probe Head

Coxial WLCSP Probe Head

Product Description:

Support pitch 150um to 350um coaxial application

Lower dielectric constant with high temperature

Suitable for high bandwidth applications

Every probe for G/P/S maintains an independent Coaxial Channel, twin probe for differential pairs if necessary

Excellent isolation control, all metal housing

Lower loop inductance

Power Test Solution

High Power Socket

Cantilever QFN/QFP

Cantilever TSSOP

High Power Contact Finger

High Power Socket

Product Advantages

Significant high current capacity and long production life time.

Standard design is simple and low cost.

Applicable QFN,QFP,SO packages.

Shortest design and production leadtime.

High Power Socket — Key Feature

Designed for high-current and high-voltage test applications

Supports QFN, QFP, and SO packages (≥ 0.4 mm pitch)

Suitable for manual test, machine test, and burn-in test

High current capacity:

12 A continuous

Up to 150 A peak (1% duty cycle)Low contact resistance: 30 mΩ

Robust reliability:

Pin life: 1M–1.5M cycles

Socket life: > 5M cyclesWide operating temperature range: −55 °C to +150 °C

Optimized electrical performance:

Bandwidth > 2.5 GHz @ −1 dB

Inductance: 2.2 nHDurable materials: Vespel SP-1, Plavis-N, MDS-100, PEEK ceramic

Cost-effective standard design with short design and production lead time

Burn In Socket

Standard Burn in socket

Temp Self Control Burn in Socket

Temp Self Control Burn-In System

Temp Self Control Burn in Socket

Product Advantages

Independent Thermal MCC OVEN Burn-In Socket (MCC,LC,DI Etc.)

Rate Current:3A at 25℃

Contact Resistance:100mΩ max

Dielectric Strength Voltage:AC100V rms 1 min

Insulation Resistance:1000MΩ min

Temperature Range:-55℃-175℃

Fast delivery of full-made design experience

Test Interface Unit

Handler Change-Kit

Docking & Interface

Cleaning Units (TCC)

Handler Change-Kit

Product Advantages

Designed for Automation ATE Pick-and-Place handler kits

Complete design and manufacturing support

Compatible with most major handler types, including: Hontech, Epson, CCTech, JHT

Flexible design to support different handler configurations

Reliable integration for production and engineering test environments